OM OSS

Danyang Spedking Auto Parts Manufacturing Co.,Ltd.,eetablert i 2018, er en fabrikk som spesialiserer seg på design, produksjon og prosessering av terrengkjøretøyer og amerikanske pickuper. Produktene inkluderer hovedsakelig frontgitter, støtfangere foran og bak, sidetrinn og takstativ.

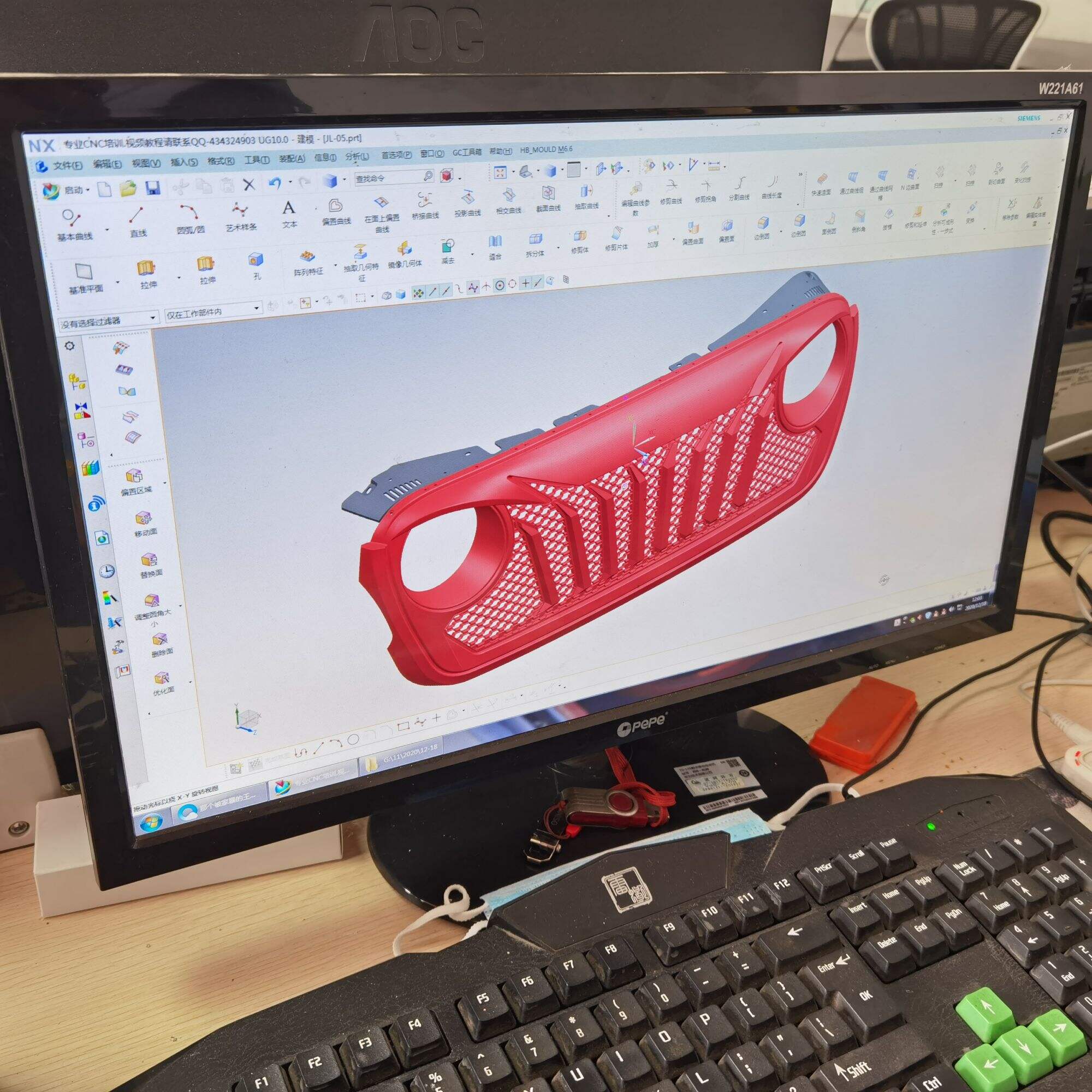

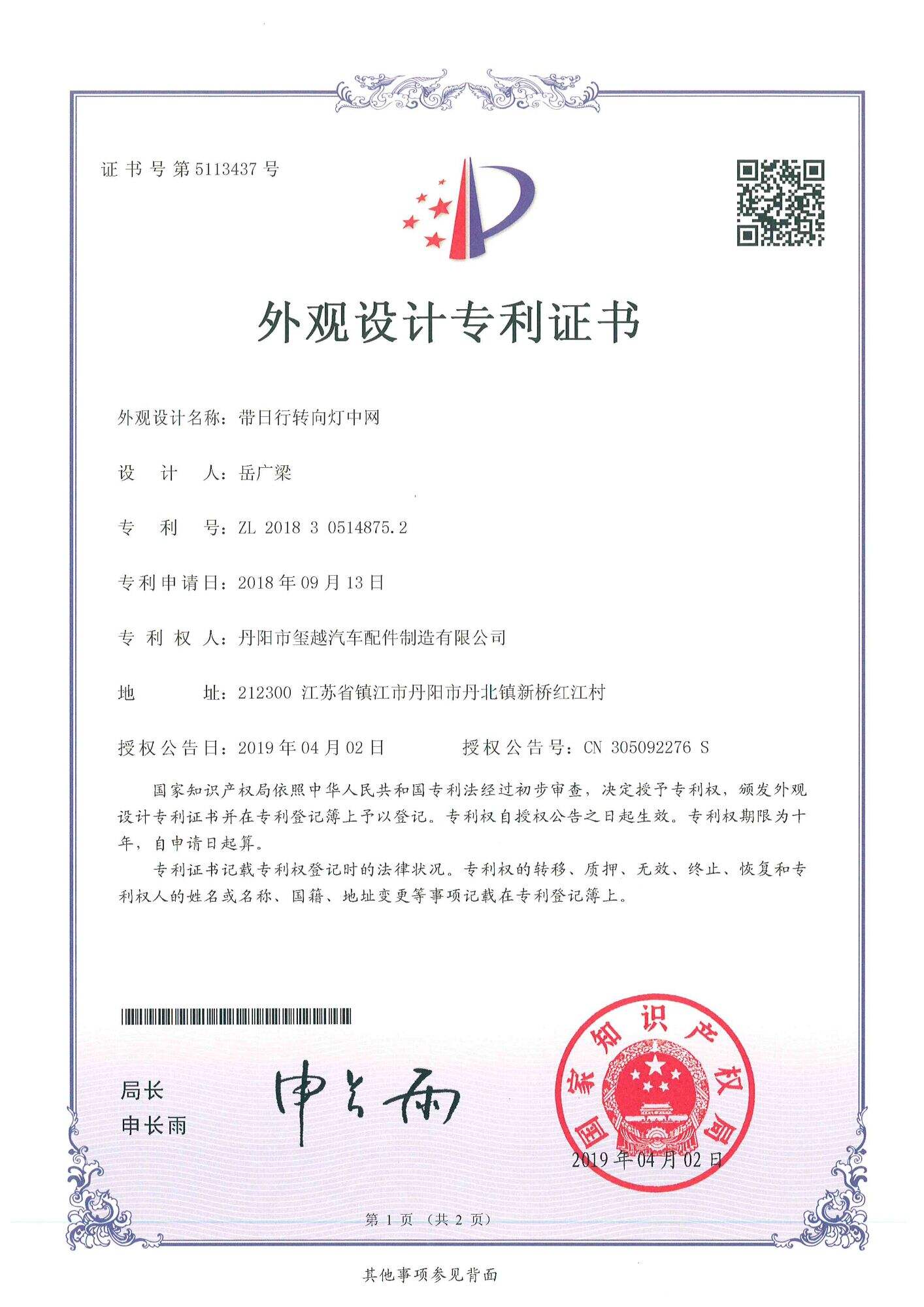

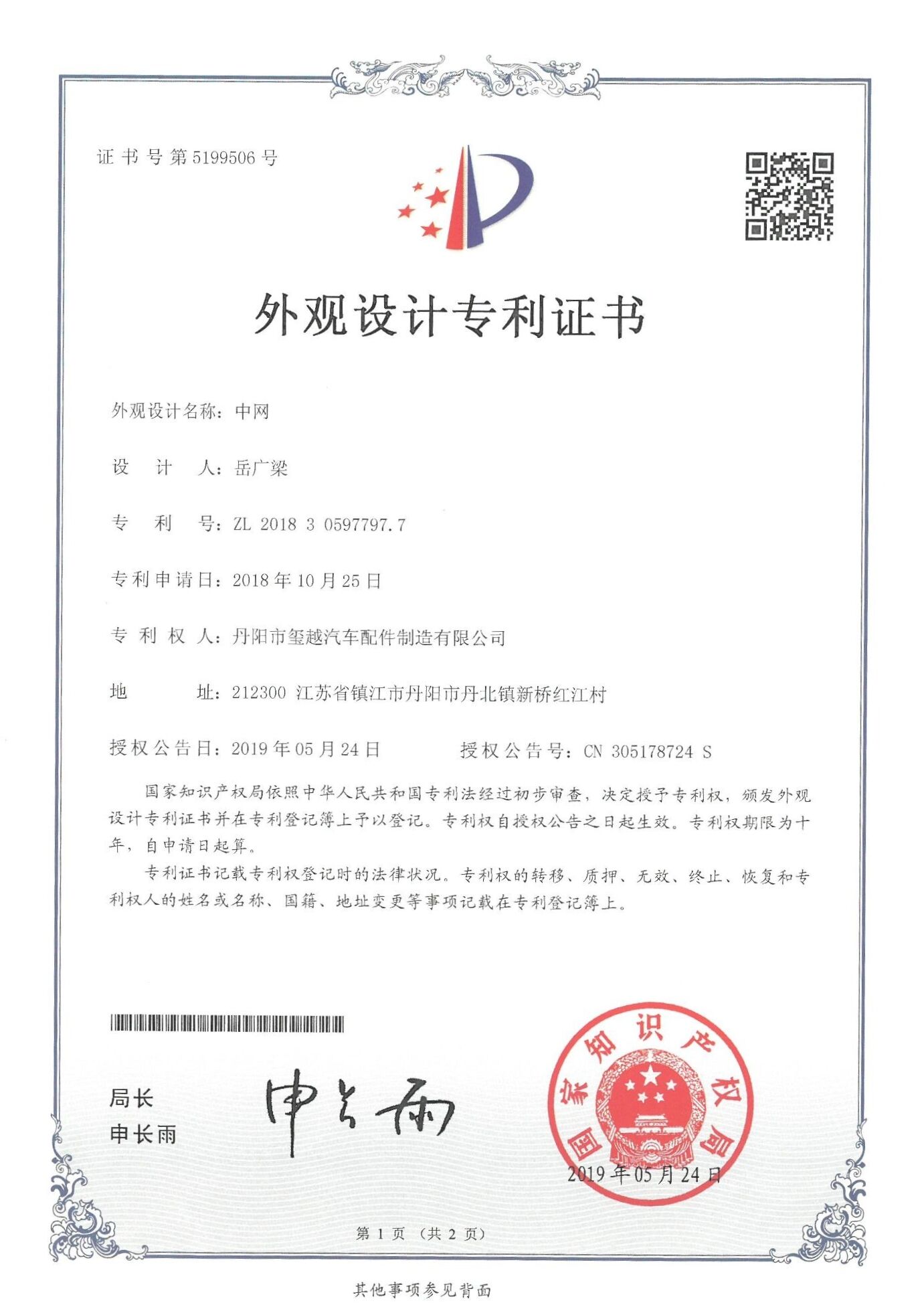

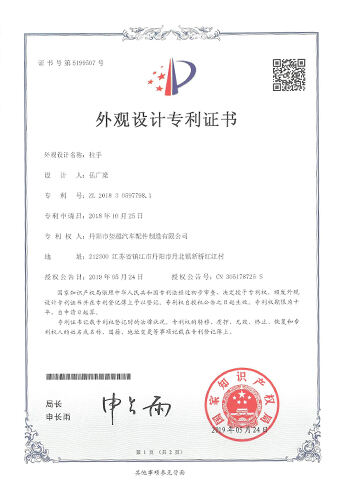

Selskapet har en rekke profesjonelle design- og teknisk personell, og har oppnådd en rekke designpatenter;

Selskapet har mange sett med avansert moderne utstyr, inkludert CNC laserskjæremaskin, haitisk sprøytestøpemaskin, etc.

Selskapet har etablert et vitenskapelig og perfekt ettersalgsservicesystem for å tilby profesjonelle tjenester til hver kunde.

prev

prev